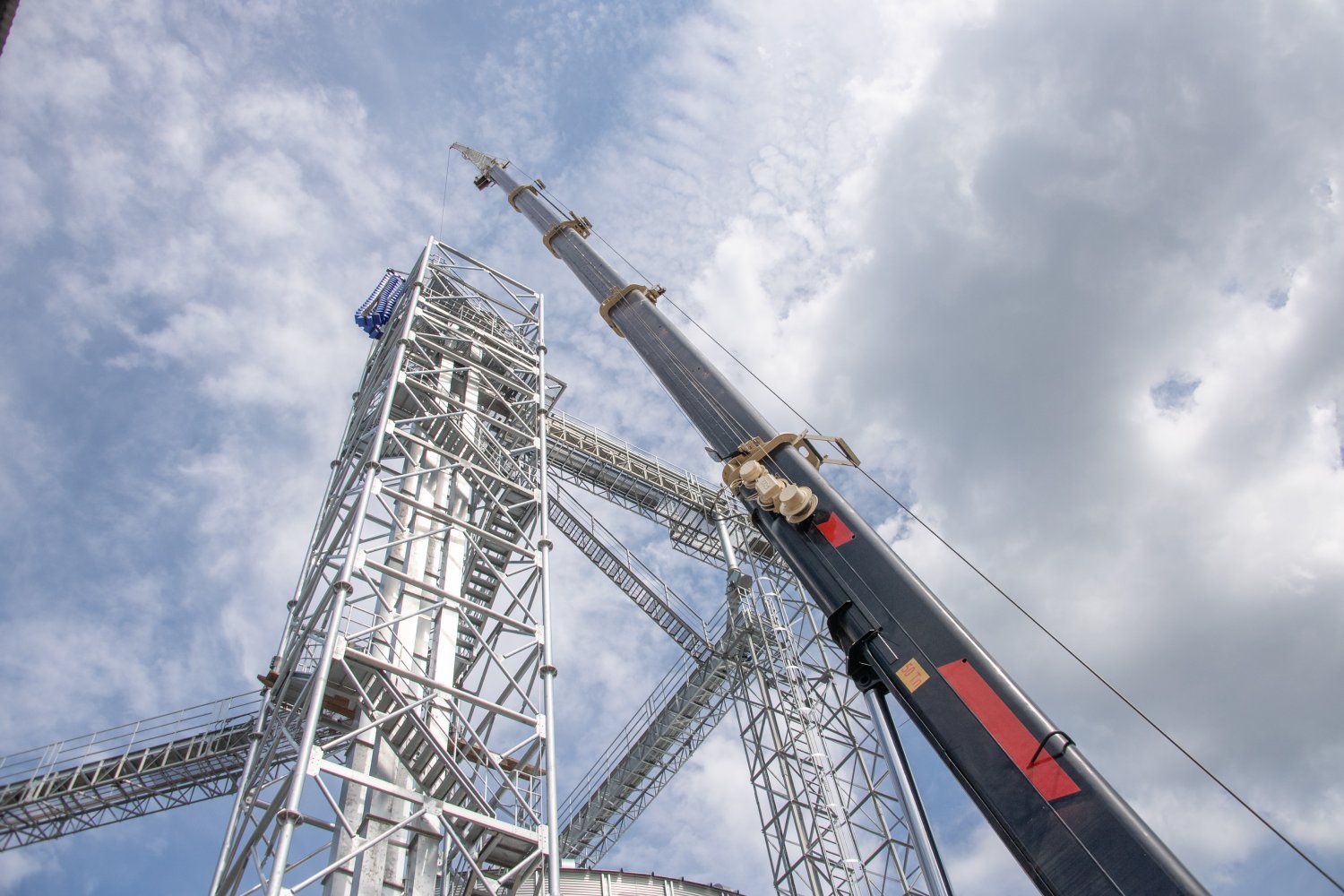

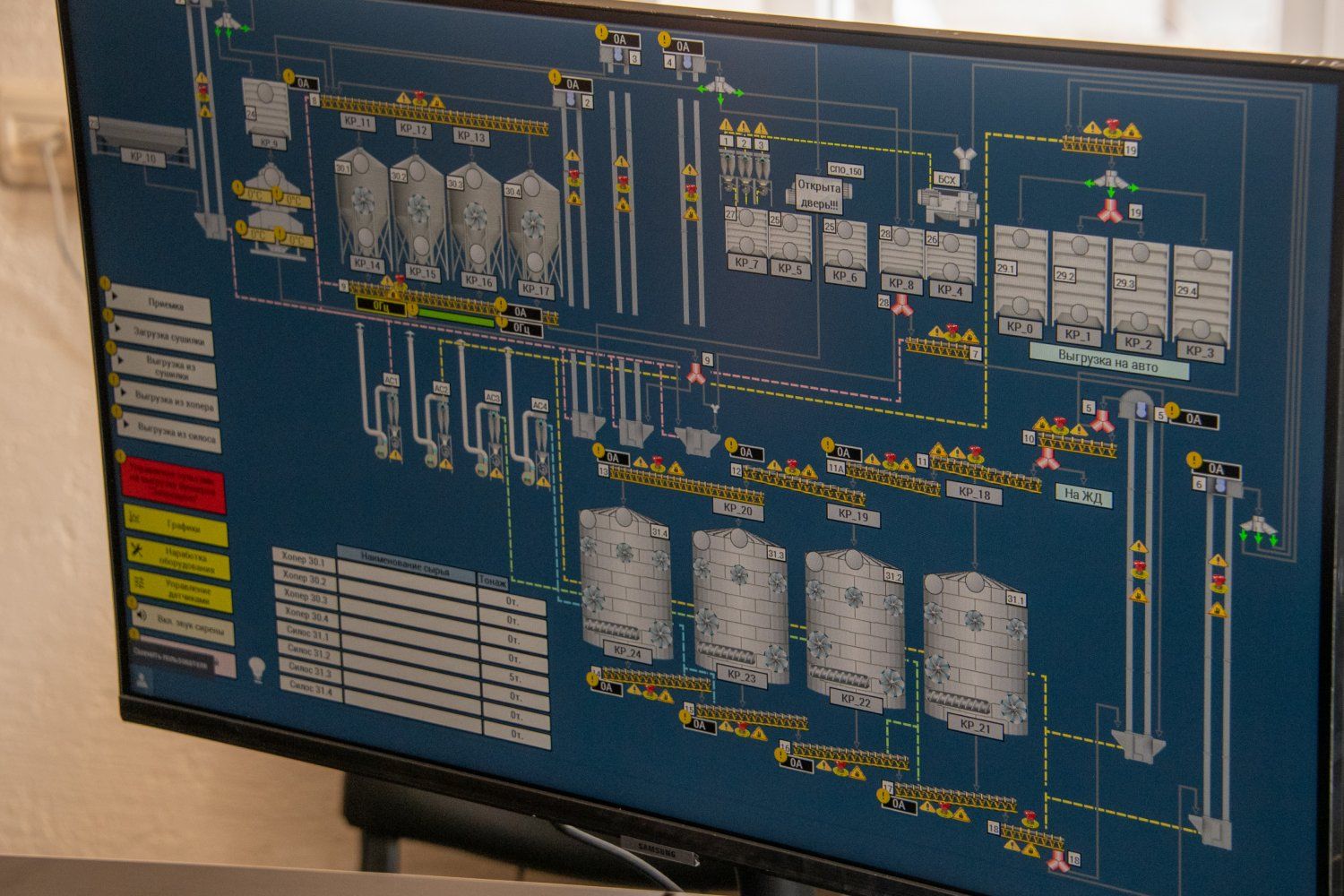

Construction of a new modern elevator began at the Novosovitskaya station in Slobodzeya district in November 2021. The design capacity is 25 thousand tons of storage. The facility is conceived as a full-cycle grain elevator, that is it involves the acceptance, cleaning, drying, storage of wheat, barley, oats, rapeseed, corn and sunflower. The initiator and executor of the idea is the local agricultural company “Trading Group” LLC. Its Manager Yevgeny Fastovets told the President today that the need to build a high-tech elevator in close proximity to land users is long overdue. Storage of crops in warehouses that do not meet the requirements, and under sheds leads to a loss of grain quality, the entrepreneur noted. According to him, a laboratory has been thought out in the structure of the complex under construction, the equipment of which will allow conducting a wide range of studies to determine the quality of grain, moisture content, weediness or contamination. The project includes a weighing and receiving department with a capacity of more than 70 cubic meters, grain cleaning equipment with a capacity of 150 tons per hour, a tunnel-type gas dryer, four silos, equipment for transportation - loading and unloading grain. Automated control of the complex will significantly simplify the process: heavy manual labor is practically minimized.

Vadim Krasnoselsky asked when the object is planned to be launched. They said that they expected to be in time for the beginning of the harvesting of grains of the first group. The harvesting campaign will begin on the 20th of June in Slobodzeya district.

The President was interested in technological details. It was noted that the current manufacturers of elevator equipment abandoned concrete structures, preference was given to galvanized metal. They say that with proper installation and the right engineering approach, the service life of elevators made of this material reaches 25 years. Another advantage is the speed of construction. The PMR President was told that vertical thermal cables are hung inside the silo, in which numerous temperature sensors are mounted, located at a distance of 1-1.5 meters from each other for better and longer preservation of grain. If the temperature rises, the information will be sent to the central control panel of the elevator and the aeration system will automatically turn on – the fans will supply additional air to the silo. They will carry out recycling – grain transfer, if this measure is not enough. The President asked about future plans. They say that a second complex for 8000 tons of grain is to be launched. There will be two more reception areas, eight silos and an additional dryer tower. The installation of a second scale and the organization of a through passage will improve logistics, Slobodzeya farmers shared their design developments. There is no facility of this level in neighboring states, the PMR President was told.